Hygienic Design and Sensors | New available guideline

Available now in our catalogue

Sensors can offer great benefits for inline quality control, but they must be designed and applied as described in the new EHEDG Guideline 37 'Hygienic Design and Application of Sensors'. Working Group chairman Holger Schmidt invites you to join his group and contribute to a follow-up document aimed at sensor suppliers, and builders of food processing plants and food processing machines.

EHEDG has just published a comprehensive hygienic design guideline (Guideline 37 – Part 1) dedicated to the hygienic design of sensors.

Chair of the Working Group Sensors, Holger Schmidt (Baumer): ‘Sensor technology is emerging to become the single most important driving innovation in optimizing food safety.’

This new guideline covers all food contact processes, including wet, dry, and powder, focusing on the product contact area of the sensor. Aside from the certified sensor itself, it is just as important to ensure hygienic integration into the process. This document will help define those hygienic requirements and provide guidance on how to use them.

Schmidt: ‘There is a trend over the last several years towards more automation, which in turn requires more information out of the processes, so the sensors are gaining importance.’ Without widespread use of sensors, food producers cannot expect to remain competitive. Sensors now allow for inline quality controls which enable adjustment during the ongoing process. Inline quality controls enable producers to maintain the corridor they’ve pre-defined for their production. Development is always a match of interests. Therefore, working in a group like this Working Group 37 helps not only sensor suppliers, but also enables the end users to get an insight of what is to come and to ensure that what is developed matches their requirements.’

A primary aim of the Working Group 37 was to support automation in a way that the process itself does not suffer and that end users are supported in utilizing the equipment, while still getting the signals they need for quality improvement and sustainability. This process requires a sensor that is installed the right way and supplies a high quality signal whenever needed. Therefore, a strong focus was placed on a customer and user-centric setup of the guideline that gets into the nitty gritty of dealing with the different technologies in process automation sensors.

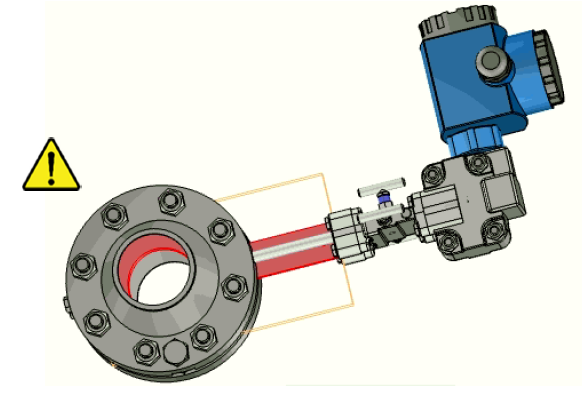

This new document provides a practical guideline to choose and install sensors according to the hygienic requirement of the application. EHEDG Guideline Document 37 also helps to define the hygienic requirements for the sensors and offers guidance for how to use them. 3D drawings display critical or interesting hotspots in the sensor design requiring access.

A subsequent guideline is in process for the designers and developers, as well as for sensor base plant, and machine builders. The combined knowhow of the three groups allows for the development of another valuable new guideline to supply the best usability and assist the industry. Schmidt: ‘Both guidelines serve the basic aim of EHEDG: to improve the industry.’