Global Events

Hygienic Engineering of Bulk Pack-off Systems in Process Lines for Dry Particulate Materials | New available guideline

Now available in our catalogue

Developers of pack-off systems and food processors can refer to this new document to ensure optimal food safety and food quality control throughout their entire food processes, including in the packaging stage. The new guideline has been developed by a multidisciplinary team of food and ingredient producers and pack-off food equipment suppliers. But to what extent are pack-off systems still considered to be part of a food processing production line?'.

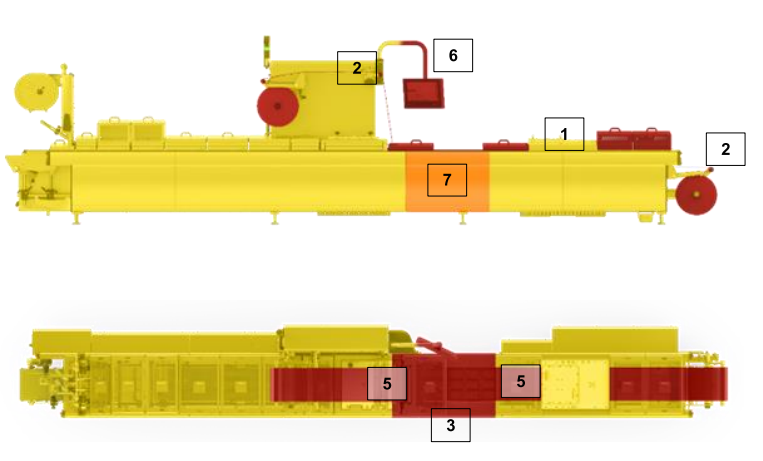

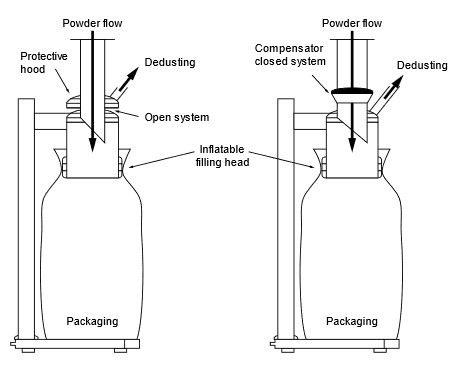

Edyta Margas, Global Head of Food Safety (Bühler), member of the EHEDG Working Group ‘Dry Materials Handling’: ‘I think they are still a large part of food processing. When we talk about pack-off systems for dry particulate materials, the scope covers the equipment, and so inevitably hygienic design. Pack-off systems for dry particulate materials are important links in supply chains for various types of food products. When correctly designed in compliance with this EHEDG guideline, pack-off systems will be cleaned more effectively, and will protect the dry particulate materials from chemical and biological contamination. This new document covers the most widely applied equipment used in pack-off systems, from the hopper, to the metering and weighing systems and up to the filling heads. It should be pointed out that the current guideline focuses exclusively on equipment used for business-to-business packaging, mostly large industrial containers, and not on equipment used for consumer packaging like small sachets or pouches.

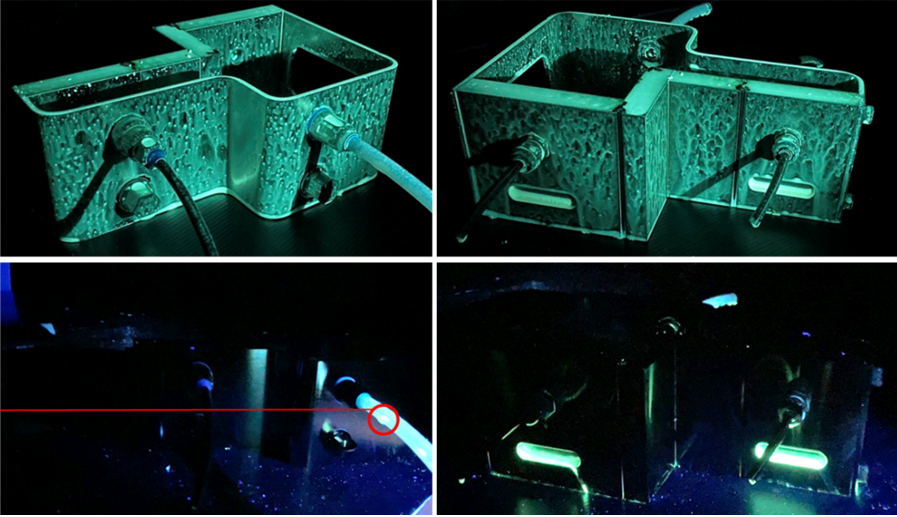

The closer to the final packaging, the riskier it becomes if contamination is introduced. Pack-off systems usually represent the last step in a dry particulate production process on site, so there will not be any further processing. That’s why it is fundamental to prevent contaminants from entering the packaging containers. Correct hygienic design of these pack-off systems will help food ingredient producers to avoid last minute cross-contamination from other food products – e.g. moisture, dirt, dust, or bacteria – entering the dry particulate materials packaging. Consequently, properly designed and cleaned pack-off systems will also reduce the risk of product spoilage.’