- Exposants & Partenaires

- Tous les sponsors et partenaires

The technology for best-level surface quality

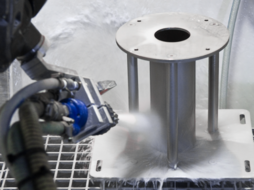

SublimotionProcess® is a cutting-edge technology developed by Phibo Industries, designed to provide unparalleled surface treatment for stainless steel.

The objective

Achieving optimal cleanability: At the heart of SublimotionProcess® lies the objective of obtaining surfaces that are not only highly resistant to corrosion but also exceptionally easy to clean. With SublimotionProcess®, achieving an optimal cleanable surface is not just a goal but a guarantee. By projecting specific particles in a controlled manner onto the surface of stainless steel, SublimotionProcess® removes all contaminants, resulting in a reconditioned surface that is pristine and ready for use in even the most demanding environments.

The perfect combo

Best-level results through the perfect alignment of machine and suspension: SublimotionProcess® combines advanced technology, refined process parameters, and a unique premium suspension. The installations seamlessly integrate SublimotionProcess® technology and process monitoring into cabinets, platforms, or production lines, so the inert suspension - an aqueous suspension of tiny, well-determined particles – available exclusively in Intermediate Bulk Containers (IBCs) from Phibo Industries – can ensure the precise cleaning and conditioning of the surface microstructure. Technology, process engineering and medium become one in this one-step process.

The outcome

The key advantages of SublimotionProcess®

- Improvement of Ra and surface topography

- Very efficient cleaning and a stunning finish

- Isotropic surface

- Closure of micro cracks and perforations

- Hydrophobic properties

- Prevention of contamination

- Optimal corrosion resistance

- Safety for both co-workers and the environment

- Elimination of static electricity

The approval

Validated and certified by some of the most important authorities: Rest assured, SublimotionProcess® has undergone rigorous validation and certification by preeminent authorities in the field such as EHEDG, ArcelorMittal-OCAS, Belgian welding institute and the Universities of Leuven and Ghent. So don’t just take our word. Instead, take theirs!

Products/ services

Ready-to-use-solutions: Transform your surface treatment processes effortlessly with our standardized cabinets and platforms. These units allow for instant incorporation of SublimotionProcess® technology into your facility, enhancing surface quality for components in various sizes.

The solution-specific advantages:

- Fast delivery time

- Budget-friendly solution

- Standard yet configurable to a certain level to meet specific needs and/or preferences

Custom engineered solutions: Experience limitless possibilities with our custom surface solutions, designed to meet the unique needs of your production facility. From small-scale components to large-scale operations, we work closely with you to create a custom SublimotionProcess® solution that exceeds your expectations in every way.

The solution-specific advantages:

- Flexibility for components of any size and shape

- Customized configurations for optimal performance

- Advanced automation options for enhanced productivity

- Comprehensive support from concept to implementation

Services to level-up your operations

Explore how our tailored service solutions can amplify the performance and reliability of your SublimotionProcess® installation(s). Designed with industrial users in mind, these forms of service are geared towards optimizing your production processes and maximizing efficiency.

Address

Phibo Industries

Nieuwe Pontstraat 23,

9600 Ronse,

Belgium

Contact Information

About us

Explore the forefront of hygienic design with EHEDG at our event on

the 2 & 3 of October in Nantes.

Join industry leaders in achieving hygienic excellence by design. See you in Nantes!

Want to stay updated?

Subscribe to our newsletter

Get the latest hygienic design news directly in your inbox.

Still have questions?

Visit our FAQ section

Contact us

✉events@ehedg.org

☎+31 610 216 958